Porsche Ceramic Composite Brakes (PCCB) is now synonymous with a thing, that has always been treated with top priority for Porsche. Because sports cars from Zuffenhausen have always been equipped with outstandingly powerful and durable brakes. Porsche’s stoppers are the reference in almost every segment, they participate in. It is therefore not surprising that Porsche was the first vehicle manufacturer ever to use brake discs made of ceramic composite with involute cooling channels. In the meantime, the Porsche Ceramic Composite Brake is a matter of course on all Porsche super sports cars.

Porsche introduced the 996 Turbo at the start of the new millennium. As an option, the 420-hp 911 was equipped with the newly developed Porsche Ceramic Composite Brake (PCCB). This is a brake system with a perforated brake disc made of carbon-fiber-reinforced silicon carbide. This material is lightweight, highly torsion-resistant and enormously heat-resistant. In its material composition, the PCCB brake is similar to the brake discs used in motorsport since the 1980s. The PCCB brake system was recognizable by its yellow brake calipers.

The advantages of brake discs made of carbon-fiber-reinforced silicon carbide, colloquially known as ceramic brake discs, are obvious. Compared with standard steel brake discs, they save over 50 percent of weight. Porsche sports cars with Ceramic Composite Brakes are therefore on average 20 kilograms lighter. Since these 20 kilograms count toward the unsprung masses, the saving is also very noticeable in the car’s dynamics. The effect is identical as a switch to lighter wheels. Sharper handling and lower fuel consumption are the result.

However, the material composition also offers other advantages. First of all, the friction coefficients of Porsche’s Ceramic Composite Brake discs are very high and consistent. Even at temperatures above 1,000°C, the friction coefficient of these discs does not decrease. Therefore, there is no brake fade during sporty driving. (Brake faed describes a reduction in braking efficiency after repeated, heavy use) Even in the wet, the response of Porsche Ceramic Composite brakes is first-class. Despite their lower weight, the PCCB brake discs are considerably more durable in everyday use than their steel counterparts. Added to this is the rust resistance of the ceramic discs. Salt corrosion in winter is therefore not an issue.

Of course, all these advantages do not come for free. Compared with steel brake discs, the production effort is immensely high. The materials are also anything but cheap. That’s why the Porsche Ceramic Composite Brake costs a high four-figure surcharge as an optional extra, if it’s available. As of May 2022, PCCB is reserved exclusively for models on which it is standard equipment. PCCB discs and pads as a spare part quickly run up to 20,000 euros. Retrofitting is therefore not really an option.

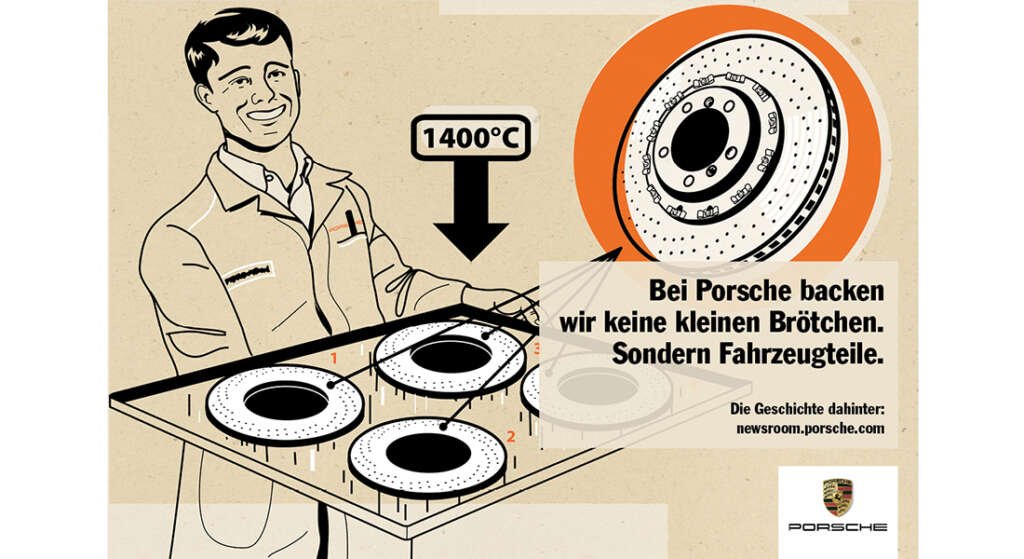

Porsche’s composite brakes go through a very long process before they can be fitted to the car. The plastic and carbon fiber are first mixed and placed in the mold. This is done in two layers. Aluminum parts are placed between the two layers to leave out the cooling channels. At around 200°C, the material is then pressed into a brake disc’s shape with about 20 tons of pressure.

After an intermediate surface treatment, the PCCB discs are baked. This takes place in a special oven that gradually raises the temperature over a total of 48 hours. Throughout the baking process, the temperature peaks at approximately 1,000°C. The chemical reaction in this process is called “carbonization”. During that process, the plastics contained convert into carbon.

In the next step, “silicizing,” a fine, ceramic silicone powder is added to the discs. In a process lasting another 24 hours, this material is gradually heated to 1,400°C+ in a high vacuum. During this process, the material liquefies and bonds with the rest of the disc. The result is the the forementioned silicon carbide. Finally, the ceramic brake discs are given an appropriate anti-oxidation coating for a longer disc life. After final machining and balancing, the disc is ready.

Despite the very high production and development effort, PCCB cannot cover every application. The spread is greater than with “normal” steel brakes. However, Porsche Ceramic Composite Brakes are a compromise that must also function well in everyday use. So anyone who thinks they can drive Nordschleife laps for days on end with the PCCB without brake wear is mistaken.

In everyday use the Porsche with Ceramic Composite Brake is very stable. However, at extreme temperatures, for example in race track use, the brake pads can soften and even melt. The result is smearing brake pads that later glaze. This can also damage the brake disc. But there is a remedy in the form of racing brake pads from the accessories.

Because of the high cost of replacement, trackday drivers therefore prefer to use steel discs. After all, even a ceramic disc can’t possibly withstand days of track use without wearing out. However, retrofitting to steel discs is not too complicated an undertaking. In most cases, the saddles can be retained.

Under high thermal load, supposed cracks form on the surface of the brake disc. These are spalling of the surface. But unlike on steel discs, they are no reason to panic. They do indicate high loads, usually racetrack use, though. Unforunately, it is not possible to visually assess the real condition of PCCB discs. Without an appropriate measuring device, no layman can determine whether the disc is still healthy. This makes buying a vehicle with carbon ceramic brakes a bit more challenging. But Porsche dealers and workshops should have a bespoke measuring tool for that. However, a Porsche with ceramic composite brakes can be very interesting, especially for sporty country road drivers. After all, depending on how they are driven, ceramic brakes last almost the entire life of the car on the road.

Under normal conditions, Porsche drivers are excellently served with the PCCB. Serious racing use of the carbon-ceramic brake without adjustments should not be executed, however. From a technological point of view though, Porsche Ceramic Composite Brakes are pretty interesting. And they look damn good anyway. So good, in fact, that Jeffrey Docherty has already staged it artistically.

Elferspot magazine