Unfortunately, the ravages of time do not stop at automotive marvels.

After decades in garages, on parking lots, in the rain and in the snow, as fast as possible, crossways or simply at a leisurely pace, almost all 64s show the signs of their age. Some of them have even been repaired a time or two. Whatever happened before, we start from the beginning. Uncompromising and perfectionist, no matter which assembly group. And then it’s back to decades of riding pleasure

Welcome to the 964 workshop

The way to your 964:

- Call Manufaktur 964.

- Define your desired vehicle.

- Search for base car.

- Determine the scope of the project.

- Dismantle

- Clean

- Check

- Renew

- Repair

- Install

- Get in.

- Drive

Anyone who starts a car for the sheer joy of driving should also be rewarded with sheer joy, shouldn’t they? The 964 really invites you to simply enjoy the road. To ensure that this is the case, no screw is left untouched.

We don’t wait for faults to be fixed, we make sure that no matter what time of day or night, no matter what the occasion, and no matter what you turn the key for – your biggest concern is cornering speed.

Whatever your goal, our cars can do it.

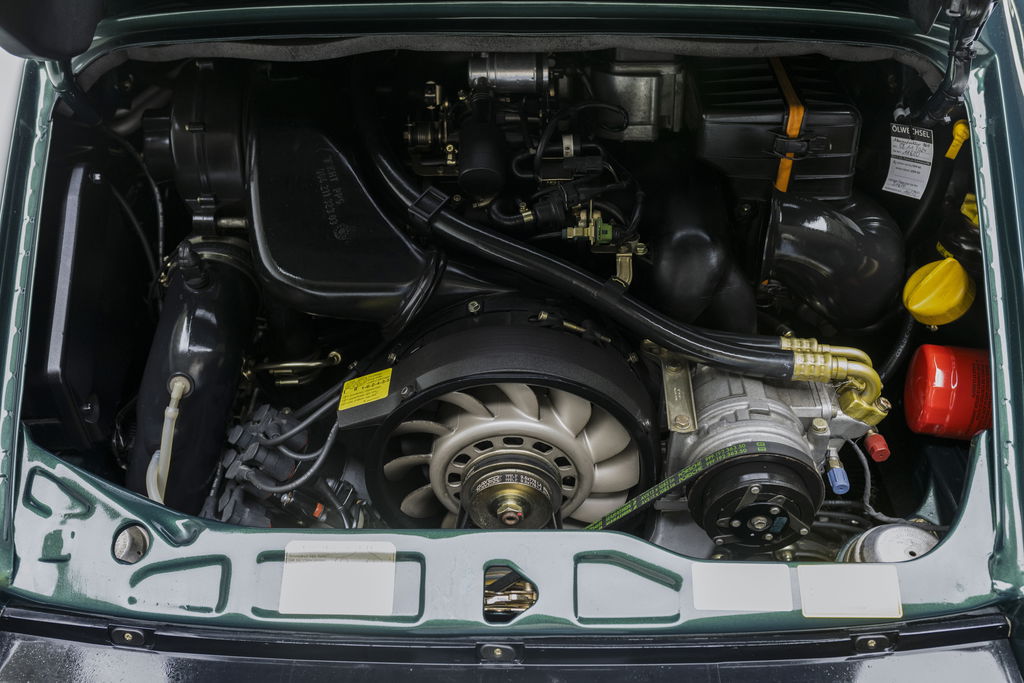

If you take away the iconic roofline, remove the defining torpedo tubes and then leave out the crest, what remains of the legend of the 911? Hardly any other feature is as engraved in Porsche’s history as the fan wheel of the six-cylinder engine in the rear. But there is so much more than just a symbol behind the fan wheel and the alternator. Whether over two or four wheels, the at least 250 horses not only drive the speedometer needle forward.

We simply catch every lost horse again. And sometimes we put a few more in.

- A finely tuned chassis.

- An adapted six-cylinder engine.

- A sound system.

- Air conditioning.

Our 964 is a car that is very good at doing many things. Why shouldn’t the most beautiful thing also be the fastest? So instead of being on the trailer, the Porsche simply drives to the racetrack on its own wheels.

How radical a road car can and should be is, of course, a matter of taste.

And that’s why every one of our 964s looks exactly as it should.

Common to all:

A grin on their face.

- The straight line.

- The bend.

- The pass road.

- The highway.

- The race track.

- But sometimes also the parking garage.

The essence of a Porsche has always been driving. In every situation in life.

And that’s exactly what we live.

Perhaps we have infected you? Just be careful, the temptation won’t go away. Because we only build cars with one goal:

To exceed expectations.

Welcome to the Manufaktur 964